Radiant Glass Window Systems

Radiant Glass Window Systems

Radiant Glass Window Systems

Radiant Glass Window Systems

According to a new report, Q4, 2014 from Navigant Research, worldwide revenue from energy efficient buildings is expected to grow from $307 billion in 2014 to nearly 623 billion in 2023.

“Services that would have seemed costly or unnecessary to building owners 5 to 10 years ago – such as corporate sustainability initiatives focused on energy efficiency – are becoming increasingly mainstream,” says Noah Goldstein, research director with Navigant Research. “Energy efficiency can help governments to reduce the carbon intensity of local and national economies and corporations reduce costs as well as their carbon footprints.”

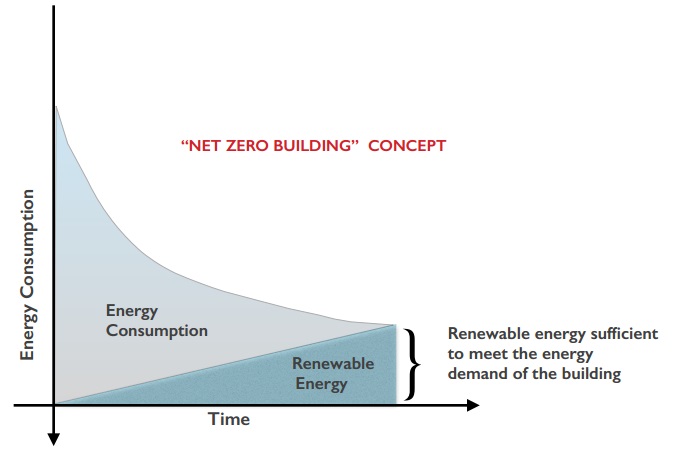

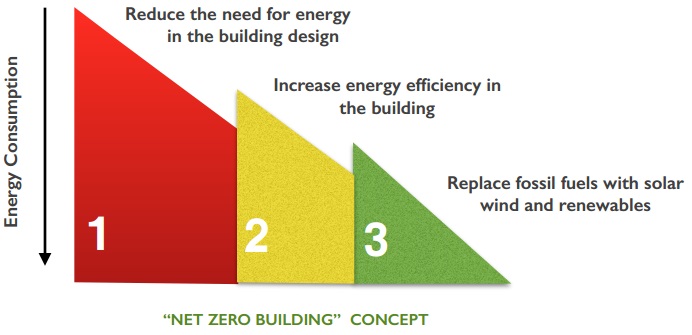

This elegant chart demonstrates that a Net Zero Building must use products that reduce energy consumption, increase efficiency, reduce wasteful energy practices and replace fossil based fuels with either onsite or offsite renewable sources.

1. Designing with IQ Radiant Glass Window Systems

2. Retrofitting with IQ Radiant Glass Window Systems

3. Replacing fossil fuel based heating systems with renewables

In this hypothetical example, we purposely use a building that cannot use an on-site solar system and is all glass. The site has no room for solar panels. However, many locations in the Philadelphia urban area, brown fields, industrial sites, outside parking lots, flat roof industrial buildings, etc. are available and suitable for solar fields. The IQ Radiant Glass Window System maximizes the value of nob-fossil sources by significantly improving the efficiency of the consumption. We are sourcing and leveraging the value of the non-fossil fuel by the intrinsic efficiency of the Radiant Heating Glass. But there is even more.

Pro Forma Analysis of Architectural and Mechanical Plans of a Multi-Use All Glass Tower

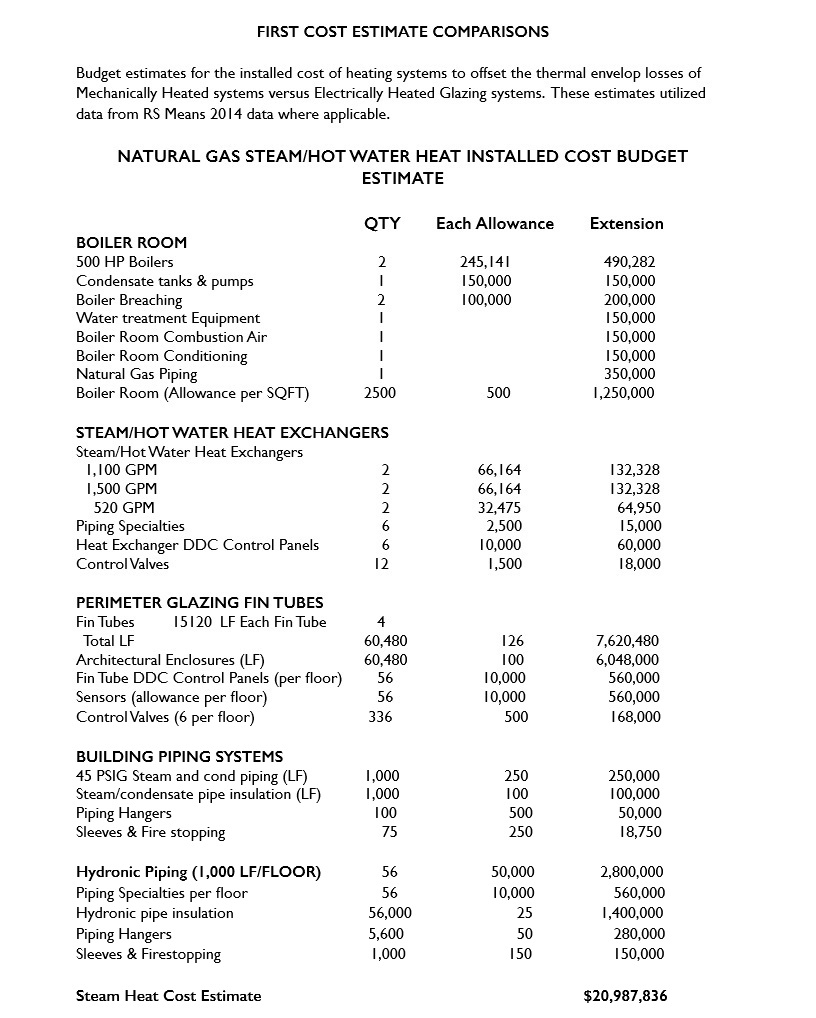

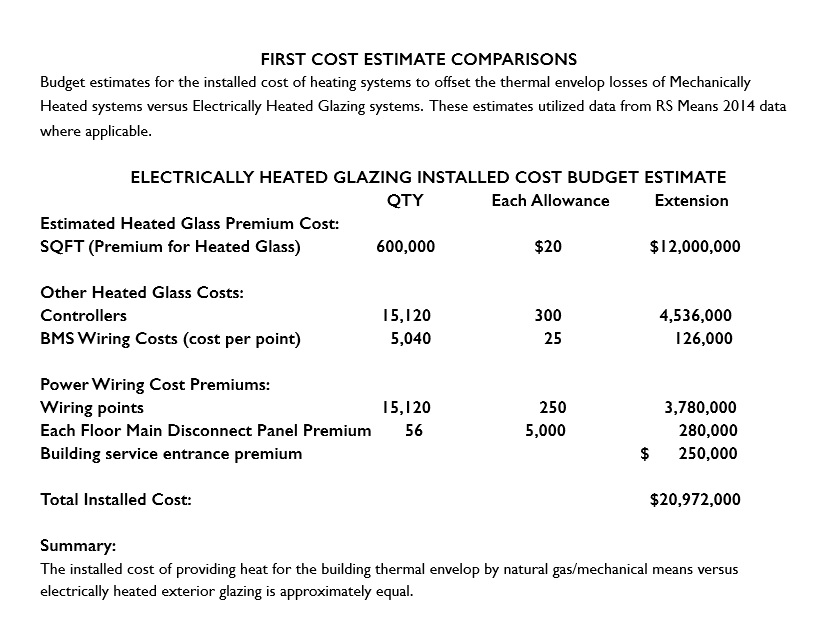

Compare and contrast heating the glazed building envelope with an IQ Radiant Glass Window System versus natural gas mechanical heating systems for this building:

• First Cost The installed cost of a natural gas steam/hot water distribution system and conventional windows is approximately equal to the installed cost of an IQ Radiant Glass Window System for the entirety of this building’s thermal envelope.

• Annual Energy Operating and Distribution Cost Using electrically heated glazing systems will save approximately $390,000 per year (a 25% annual energy savings).

• Condensation Avoidance A heated glazing system will offer the best means of condensation avoidance in high humidity spaces such as the Pool and Spa areas.(No value Assigned)

• Building Temperature and Building Management Control Electrically heated glass provides controllers with “software points” with glazing panel pane by pane resolution of control. Steam/hot water heating of glass panes will require extensive valve control, with remote sensors and floor by floor control panels. For cost sake, mechanical control systems using “hardware” points could never match that of electronically controlled systems. We believe this is self-evident and requires no additional justification. ( No value Assigned)

• Maintenance Cost and Longevity of Heated Glazing Systems Heated Window Glazing Systems have no mechanical moving parts and require little or no annual maintenance, an annual savings of $500,000 a year can be anticipated.

• Sustainability The building to be sourced from solar or wind powered sources thereby reducing the building carbon foot print from 32,596,368 lbs. CO2 per year to zero. ( No value Assigned)

ANNUAL PRO FORMA ENERGY OPERATING COST

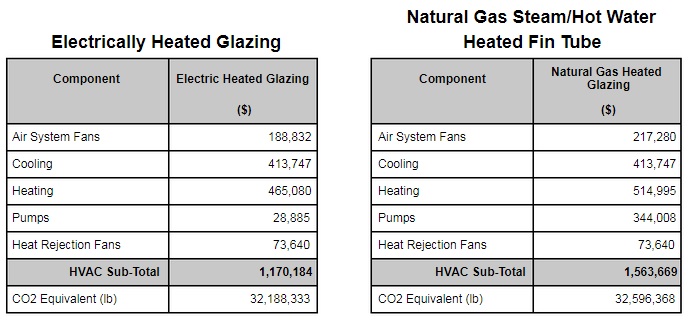

Using Carrier E20-II Hourly Analysis Program for energy modeling, local ASHRAE weather data, generic HVAC equipment compliant with ASHRAE Standard 90.1-2010, ventilation in accordance with ASHRAE 62.2-2010, natural gas cost - $0.80 per therm, and power cost - $0.90 per KWH, we assume the following energy cost comparison:

The differential heating cost includes hot water heat for air systems for both analyses, with the only differentiation being electric versus natural gas fin tube heat for perimeter glazing.

The energy savings using electrically heated glazing systems are realized by the applied energy differences due to lower heat settings, lower u-values of the glass, efficiencies related to radiant heating glass and associated energy costs to deliver the heat to the building envelop thermal load. Given that electrically heated glazing does not require pumps, fans, a burden imposed by 80% (at best) efficient gas steam boilers, heat exchanger and piping losses, the annualized energy cost savings is not difficult to realize.

Summary:

The annual energy cost savings of electrically heated glazing will yield approximately $393,485 per year in natural gas and electrical costs.

Note:

Additional significant savings will result and vary with various glass selections power management systems and glazing configurations

Designing with IQ Radiant Glass Window Systems and using off site non fossil energy sources from solar or wind powered generation will reduce the building carbon foot print by 32,596,368 lbs. per year

The “Net Zero” goal is accomplished with collaboration and participation of the building management team, the local utility for use of the grid and off site providers of solar, wind and other non-fossil fuels

The equivalent savings in CO2 from this one building is the equivalent of an urban forest area in Center City Philadelphia, the size and area of the above map

© 2016 Energwindows | All Rights Reserved